Sukhoi Superjet 100 (SSJ100)

Sukhoi Superjet 100 (SSJ100) user+1@localho… Wed, 08/31/2022 - 21:17 The Superjet 100 (SSJ100) is a clean-sheet airplane that was “developed and [is] produced by Sukhoi Civil Aircraft Co. [SCAC],” while also representing the primary “project...

The Superjet 100 (SSJ100) is a clean-sheet airplane that was “developed and [is] produced by Sukhoi Civil Aircraft Co. [SCAC],” while also representing the primary “project of the company.” While SCAC has since been renamed “Regional Aircraft – Branch of the Irkut Corp.”—the latter of which is also the EASA type certificate holder—the Superjet itself is the result of a joint venture between the Russian manufacturer and European manufacturer Leonardo. According to SCAC, the SSJ100—which is the commercial designation for the RRJ-95 type—is the first airliner that has had the engine and airframe “designed together to optimize performance,” with the airplane’s PowerJet engines being produced by a joint venture of European manufacturer Safran Aircraft Engines (formerly Snecma) and Russian manufacturer United Engine Corp. (UEC). “The first SSJ100 prototype was rolled out” on Sept. 26, 2007, in Komsomolsk-on-Amur, Russia, the location of SCAC’s final-assembly facility. Subsequently, the SSJ100 first flew on May 19, 2008, and received its type certificate from the then-Interstate Aviation Committee (IAC) Aviation Register (AR)—now known as the Federal Air Transport Agency (Rosaviatsia)—on Jan. 28, 2011, ahead of the first delivery and first commercial flight. The first production SSJ100 (Serial No. 95007) was delivered on April 19, 2011, to Armenian carrier Armavia, which operated the type’s first commercial flight on April 21, 2011, from Yerevan, Aremenia, to Moscow Sheremetyevo Airport. Following its first commercial flight with Armavia, Russian airline Aeroflot took delivery of its first RRJ-95 in June 2011—Serial No. 95008 and registered as RA89001—and began service with the type on June 16, 2011.

Beyond receiving certification in Russia, the RRJ-95B was also certified by the European Union Aviation Safety Agency (EASA) on Feb. 3, 2012, which allowed “European airlines, as well as those operating in countries which use EASA regulation as a reference standard, to accept and operate the SSJ100.” SCAC stated that EASA certification of the SSJ100 made it “the first Russian passenger ‘large airplane’” to receive “EASA CS-25 certification.” Validation of the type certificate by Mexico, Indonesia, and Laos subsequently took place in April 2012, November 2012 and December 2012, respectively. Further representing the second Russian-built airplane to achieve certification from a Western aviation authority after the Tupolev Tu-204, the first Europe export certification for the SSJ100 was received in June 2013. The first delivery to a Western customer was made to Mexican carrier Interjet at that year’s Paris Air Show, with that operator taking delivery of SSJ100 Serial No. 95023, registered as XA-JLG. The first European operator of the Superjet was Irish carrier CityJet, which took delivery of its first Superjet on May 24, 2016—Serial No. 95102 and registered as EI-FWA—as part of an order placed in October 2015 for 15 leased airframes. Following that delivery to CityJet, the operator placed the type into service on June 8, 2016. In addition to the basic SSJ100, a long-range variant of the airplane—the RRJ-95LR-100—was certified by the IAC AR in August 2013, with the upgrades to the SSJ100LR also receiving approval from EASA in December 2016.

Cabin and Baggage Capacity

According to the EASA type certificate data sheet (TCDS) for the RRJ-95B, the maximum passenger seating capacity is 103 when three cabin crew are aboard, with SCAC stating that a minimum of two cabin crew are required. The cabin itself is marketed as providing passengers with a similar amount of space to a narrowbody airplane “in a compact airliner.” Cabin dimensions include a height, in the center aisle, of 83.46 in., with the center aisle also noted for its width. The SSJ100 is also promoted as having seats that are of a comparable width to those found on “medium and long-haul aircraft,” seats that have a pitch of 32 in. in the airframe’s basic configuration. Additionally, the cabin’s overhead bins have a length of 78.74 in. and the “total baggage capability” is 1,019 ft.3, including both checked and unchecked baggage. On a per-passenger basis, the checked baggage volume is 8.83 ft.3, while the total baggage capacity is 11.65 ft.3

Avionics

Described by SCAC as being “the first 100-seat jet with a full fly-by-wire (FBW) [flight control] system,” the two required pilots operate the SSJ100 using a Thales avionics suite that has five displays and which includes Integrated Modular Avionics and back-up instruments, as well as guidance, integrated maintenance and communication and navigation systems. The FBW flight-control system is promoted as being designed to lower pilot workload, ensure that the airplane’s fuel efficiency is “maximized” and “optimize [its] handling.”

A number of avionics capabilities have been added to the SSJ since it was first certified, with a supplemental type certificate issued by the IAC AR in March 2014 confirming that the SSJ100 had the capability to “perform flights under area navigation [RNAV] in RNAV 1 and P-RNAV [precision area navigation] systems.” In December 2015, EASA similarly issued a supplemental type certificate that approved the same operations under RNAV 1 and P-RNAV. Three months after receiving Russian certification for RNAV 1 and P-RNAV, a supplemental type certificate was issued by the IAC AR in June 2014 confirming that operations in a category IIIa (CAT IIIa) environment were allowed, with that approval including crosswind weather conditions, as well as operations on narrow runways (30 m wide). Later the same year, approval was given—in the form of another supplemental type certificate which was issued in November 2014—that allowed the use of the vertical navigation (VNAV) functions of the avionics during “all stages of flight,” the benefits of which include reductions in crew workload, as well as “ensur[ing] compliance with all applicable restrictions.”

Mission and Performance

SCAC promotes the flexibility of the SSJ100, including how its performance—the range of environmental conditions in which it can operate, as well as the cruise speed and takeoff/landing performance—allows the airframe to be utilized at an increasing number of destinations. Furthermore, it is marketed as being a complementary airframe for operators with narrowbody fleets, as it can be used to replace larger airframes on routes that have seasonal demand fluctuations.

The performance limitations of the RRJ-95B type include a maximum operating limit Mach number (MMO) of 0.81 Mach and a maximum operating altitude of 40,000 ft., while also being limited to operations at airports with an elevation of 8,466 ft. or less. Although SCAC promotes the airplane’s ability to operate in a temperature range between -54° and 45°, the EASA TCDS states that operating range (the environmental ground temperature) is between -40°C and 45°C. Beyond the certified limitations of the RRJ-95B, SCAC states that the “basic” SSJ100 has a maximum range of 1,598 nm when equipped with 87 seats and assuming a passenger weight of 220 lb. (100 kg.). Although the SSJ100 – B100 model retains the same maximum takeoff weight (MTOW) as the “basic” SSJ100, SCAC advertises it as having a range of 1,646 nm when carrying “an expected payload” in standard conditions. Based on the same assumptions, the “long-range” SSJ100 increases that maximum range of the basic airframe by nearly 750 nm to 2,333 nm.

Similarly, the SSJ100’s takeoff field length (TOFL)—assuming the airframe’s MTOW, standard conditions, sea-level altitude, no wind and while operating from a dry runway without any slope—differs between the basic and long-range versions, with the latter requiring a greater TOFL than the former. Specifically, the basic SSJ100 requires a TOFL of 5,774 ft., a distance that is reduced to 5,495 ft. on airplane’s that have the “-B100 option with [the] SaM146-1S18 engine.” In contrast to the differences that are found in the range and TOFL of the basic and long-range versions of the SSJ100, the landing field length necessary for both is a common 4,675 ft., a distance which assumes the same criteria except for the maximum landing weight.

Variants

|

Sukhoi Superjet 100 (SSJ100) |

||

|

Type Designation |

RRJ-95B |

|

|

Maximum Passenger Capacity |

103 |

|

|

Maximum Range (nm) |

SSJ100 (Basic) |

SSJ100LR |

|

1,598 |

2,332 |

|

|

Engines (2x) |

PowerJet |

|

|

SaM146-1S17 |

SaM146-1S18 |

|

|

Takeoff Thrust (lb.) |

15,400 |

16,100 |

|

Maximum Takeoff Weight (MTOW) (lb.) |

SSJ100 (Basic) |

SSJ100 LR |

|

101,148 |

109,019 |

|

|

Maximum Landing Weight (lb.) |

90,390 |

|

|

Fuel Capacity (Usable) (gal./lb.) |

4,175/27,176 |

|

|

Wingspan (ft.) |

91.21 |

|

|

Wing Area (ft.2) |

902 |

|

|

Length (ft.) |

98.23 |

|

|

Height (ft.) |

33.74 |

|

PowerJet Engines

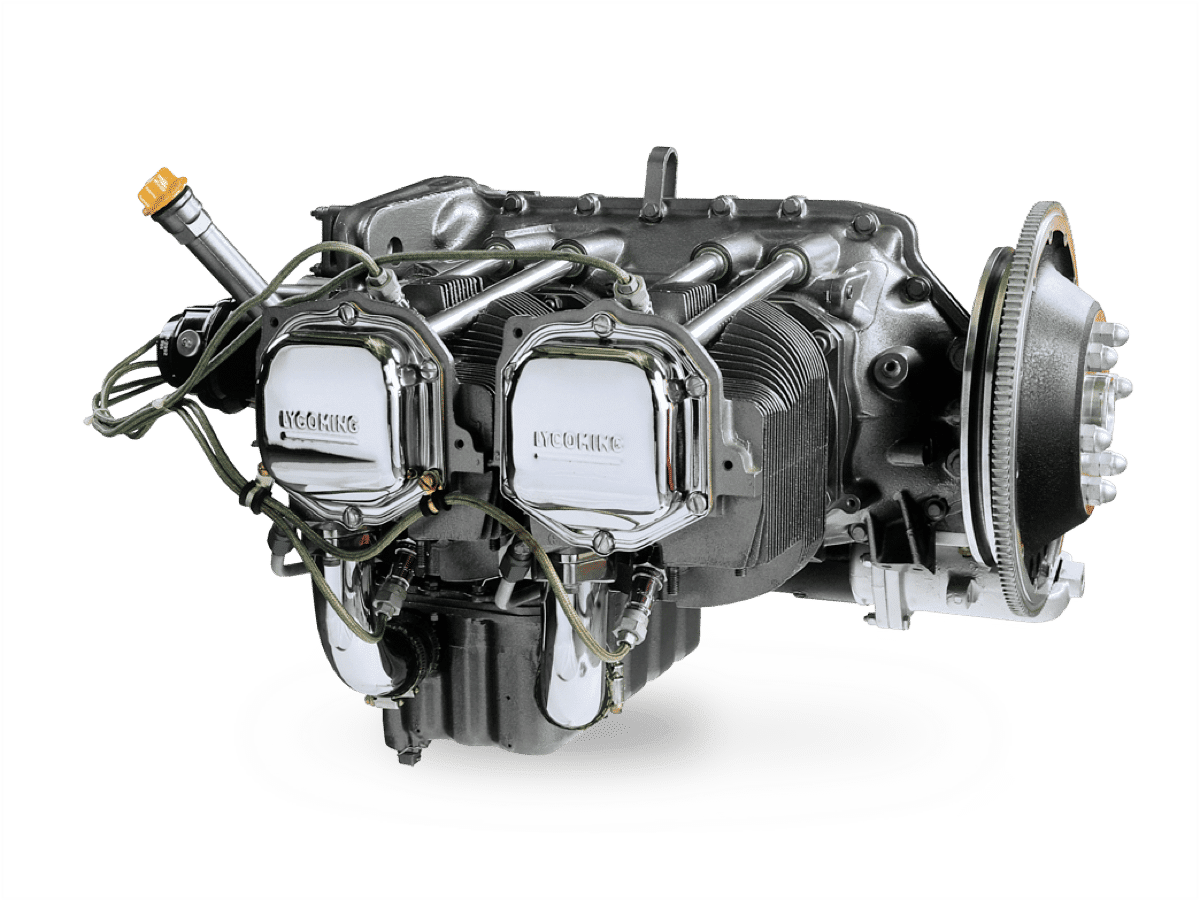

SCAC describes the PowerJet SaM146 engines as being “developed and built for the” SSJ100, while also representing a combination of new technology and then-Snecma’s experience with the CFM56. The company also states that the SaM146 has 20% fewer components, a benefit of which is the significant reduction in “operating and maintenance costs.”

Specific SaM146 components include a full authority digital engine control (FADEC) system that is a redundant, third-generation system that lowers fuel consumption while “optimiz[ing] performance.” The EASA TCDS lists two SaM146 variants that are certified for the RRJ-95B model—the SaM146-1S17 and -1S18—with the latter engine having a takeoff thrust that is slightly higher (16,100 lbf.) than the former engine (15,400 lbf.). Although that specification differs, both engine variants have a common bypass ratio (4.43) and fan diameter (48 ft. 2 in.). In addition to being installed on the SSJ100LR, the SSJ100 – B100 model is also equipped with increased-thrust SaM146-1S18 engines, with that version—which is also designated the RRJ-95B-100—differentiated from the base airframe on the basis of those more-powerful engines.

In October 2014, another supplemental type certificate was issued to SCAC which covered the SSJ100’s ability to conduct takeoffs at reduced thrust settings. According to the airplane manufacturer, the benefits of operating at those reduced-thrust settings—reduced engine speed and turbine gas temperature—include lower loads being put on the engine and “extend[ed] engine lifetime,” which lowers the overall maintenance costs.

SSJ100 and SSJ100LR Design, Limitations and Specifications

Although all versions of the SSJ100 share common dimensions, a 90,390-lb. maximum landing weight and a 4,175-gal. usable fuel capacity, the basic and long-range versions of the airframe have differing MTOW of 101,148 lb. and 109,019 lb., respectively. In order to accommodate the SSJ100LR’s higher weight, the airframe’s wings have been strengthened, while also being equipped with an SaM146 engine variant that produces 5% more “takeoff thrust performance.”

SCAC states that a number of other improvements have been made to the SSJ100 since it first received Russian certification in 2011, improvements that include an expansion of the previously discussed temperature range to 45°C, which was approved in May 2012. Later that year, in November 2012, the airplane’s operational conditions were expanded in “the high north latitude area.” As a result of the flight testing for that expansion, avionics functioning—including satellite-navigation systems GLONASS and GPS, as well as the airplane’s inertial reference system (IRS)—was confirmed during operations in temperatures as low as -54°, as well as “up to 78°” in the high north latitude area.

A structural update that is available for the SSJ100 is a “new wingtip configuration” that incorporates horizontal winglets that are marketed as saberlets—“saber-like horizontal wingtips”—which were a collaboration of SCAC and Russia’s Central Aerohydrodynamic Institute (TsAGI). According to the airframe manufacturer, airplanes equipped with saberlets have fuel consumption that is lowered by a minimum of 4%, while also improving the airplane’s performance during takeoff and landing. The takeoff and landing performance improvements are described as being of particular value to operators which utilize the SSJ at high-altitude airports and in hot-weather conditions, as well as those that operate it from “regional runways.” At the time of the first flight of an equipped airplane, it was expected that saberlets would included on SSJ100 configured to operate from London City Airport. The first flight of a sablet-equipped SSJ100 took place on Dec. 21, 2017, from Moscow Zhukovsky Airport, with the upgrade promoted as saving operators as much as $70,000 “per year per aircraft.” Following the completion of a flight-test program that involved a pair of prototypes—Serial Nos. 95157 and 95032, basic and long-range SSJ100, respectively—SCAC announced in 2019 that it had received Major Change Approval from Russia’s Federal Air Transport Agency. The company also stated that Russian regional airline Severstal Aircompany received the first saberlet-equipped SSJ100 to be delivered to be a customer (Serial No. 95181 and registered as RA89135).

SSJ100 Economic and Environmental Performance

In comparison to competing airframes, SCAC states that the SSJ100/95 provides cost savings of 10%, as well as having reduced capital and maintenance costs, fuel burn and weight-related fees. The reduction in weight-related fees is a result of the airframe’s reduced MTOW, while the SSJ’s aerodynamics, engines, FBW flight controls and performance contribute to the lower fuel consumption. Furthermore, a number of factors in the airplane’s design—namely, the utilization of computer-aided three-dimensional interactive application (CATIA) and the fact that it is “design[ed] to maintain”—are promoted as reducing the cost of maintenance.

From an environmental perspective, the SSJ100 is marketed as emitting less carbon dioxide (CO2) and nitrogen oxides (NOX), while also being “compliant with existing and future gaseous emissions and noise requirements.” Specifically, the SSJ100 is described by SCAC as going beyond the International Civil Aviation Organization’s (ICAO) Committee on Aviation Environmental Protection CAEP6 standards by considerable margins. For airplanes powered by SaM146-1S17 engines, those margins range from 20% better than the CAEP6 standard for NOX emissions to an 84% margin for unburned hydrocarbons (UHC), with the carbon monoxide and smoke emissions below that standard by 33% and 44%, respectively. SCAC also states that, on a 1,000-nm trip, the CO2 emissions per trip are 1.5 tons lower than the SSJ100’s direct competitor. Another ICAO standard that is met are the Chapter 4 noise regulations, which the airframe complies with thanks to the SaM146’s long-duct nacelles that are described as being “high tech” and “designed to optimize acoustic performance.” Because the SSJ100 meets the Chapter 4 regulations, it is promoted as having the capability to conduct operations “from any airport.”

Modernized SSJ100

In addition to improvements such as saberlet wingtips, SCAC is also working to reduce the number of imported components found on the SSJ100. According to type certificate holder Irkut Corp., the goal of the Superjet-New program—which is also designated SSJ-NEW and RRJ-95NEW-100—is to use as many Russian-made components as possible, with the company stating that, in particular, “[t]he number of American components will be reduced by several times.” However, the goals of the program go beyond the use of “alternate suppliers”—which is noted as improving the flexibility of “after-sales support”—to also the lowering of operational costs, with the updated airframe also increasing the maximum landing weight to 42 metric tons and making winglets standard. Development of the SSJ-NEW began in 2019, with the updated airframe expected to receive approval in 2023. As of February 2022, the amount of non-Russian components used in the SSJ-NEW was below 10%, excluding the SaM146 engines.

Program Status

SCAC describes itself as being “founded in 2000 in order to create and develop new models of commercial aircraft,” while the Komsomolsk-on-Amur “branch” of the company was created in 2005 for the purpose of manufacturing the SSJ100. The “first engineering development” airframe was displayed in 2007—ahead of the May 2008 first flight—and the first production airframe was produced in 2010. Beyond the final assembly of SuperJet airframes, other SCAC work conducted in Komsomolsk-on-Amur includes fuselage assembly, SSJ testing and systems installation. Sukhoi also manufacturers Superjet components such as the center section; fuselage parts F2, F3 and F4; high-lift devices and wings in Komsomolsk-on-Amur, while the production of fuselage parts F1, F5 and F6—as well as the empennage—takes places at Sukhoi facilities in Novosibirsk. The production of composite parts is done by Voronezh Aircraft JSC in Voronezh, and the painting of the SSJ100 and the outfitting of the interior are performed by Spektr-Avia and Aviastar-SP, respectively, with both of those tasks noted as occurring in Ulianovsk. SCAC’s delivery center, as well as the flight-test center—where it conducts both flight and ground testing—are located in Zhukovsky.

The international portion of SCAC is SuperJet International (SJI), a Venice, Italy-based company that is also a joint venture with Leonardo and which has a number of program-support responsibilities, including global “after-sales support and services,” certification work with EASA, customization and delivery of airframes being delivered to Western customers, flight-test support and the training of flight and maintenance personnel. According to SCAC, a completion and delivery facility for airplanes destined for Western customers is also located in Venice, with that facility performing—in addition to deliveries—tasks such as the installation of the interior, painting and both ground and flight testing.

Following the Russian invasion of Ukraine in February 2022 and the imposition of sanctions by the European Union (EU) on Russia, EASA suspended the type certificate for the RRJ-95. As a result of that suspension and because it lacks “valid approvals,” the SSJ100 cannot “be operated in the EU.”

The Western sanctions imposed on Russia following the invasion of Ukraine also impact a number of SuperJet components, including some that are produced by Russian manufacturers. For example, while the SaM146 engine is manufactured by PowerJet in Russia, “at its core are many parts from Safran that are subject to sanctions,” with Safran Aircraft Engines contributing 50% of that engine. Specific SaM146 components provided by Safran include the “nacelle integration,” as well as the combustion chamber and high-pressure compressor and turbine. The result of EU sanctions is that engineers from Safran can “no longer provide” call-center service, documentation, maintenance and training. Other Western-provided components found on the SSJ100 include the auxiliary power unit (provided by Honeywell), brakes and wheels (Goodrich), electrical and hydraulic systems—provided by Hamilton Sundstrand and Parker Aerospace, respectively—flight controls and interiors (Collins Aerospace), with the sanctions meaning that airplanes will not be delivered “until they can one day be built with Russian-made parts.”

In July 2022, Irkut sent an RRJ-95NEW-100 fuselage from Komsomolsk-on-Amur to Zhukovsky for endurance tests which “will be part of the certification trials for the new aircraft.” While the previous goal of the program had been to reduce the number of non-Russian components, the program to update the SSJ “became a key priority for Irkut after Western countries embargoed deliveries of Western-built components to Russia in March” following the country’s invasion of Ukraine. Rather than simply replacing a substantial number of Western components, it is anticipated that the RRJ-95NEW-100 will now have all “components and subsystems” that are foreign made “replaced by” ones that are made in Russia. Among the changes made to the fuselage were the replacement of the doors and windows—which were formerly supplied by Collins Aerospace and Saint-Gobain, respectively—with “analogues” that are Russian made. Beyond those changes, the modified SSJ is also anticipated to replace a number of other components and systems that were European or American-made, with the updated airframe incorporating new air conditioning, fuel, electric, and hydraulic systems, as well as new avionics, auxiliary power unit, interiors and landing gear. Furthermore, the SaM146 engines are also expected to be replaced by PD-8 turbofan engines that are new, with TsAGI noting that the upgraded SSJ includes “more than 30 Russian suppliers.”

It is anticipated that first prototype of the RRJ-95NEW-100 will make its first flight in 2023, with the certification trials of the modified SSJ planned to be finished “by the end of 2023.” The delivery of the “first two serial airframes” is also anticipated to occur in 2023, while the production rate beginning in 2024 “should reach 20 jets per year.”

References

- AWIN Article Archives

- Sukhoi and Thales Commercial Materials

- EASA TCDS (RRJ-95)

- FAA Advisory Circular 90-96A

admin

admin